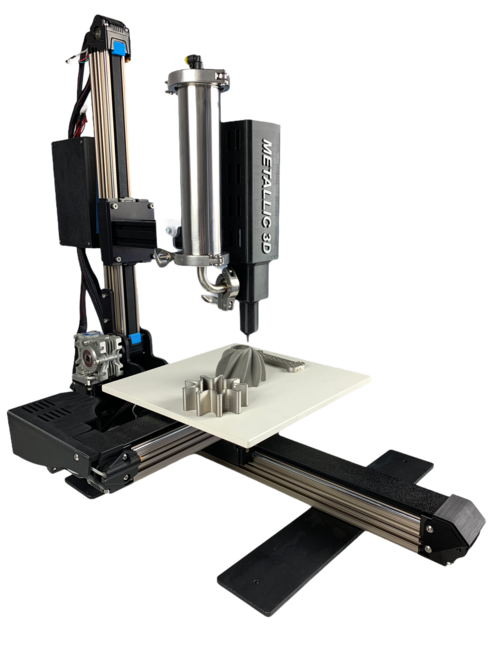

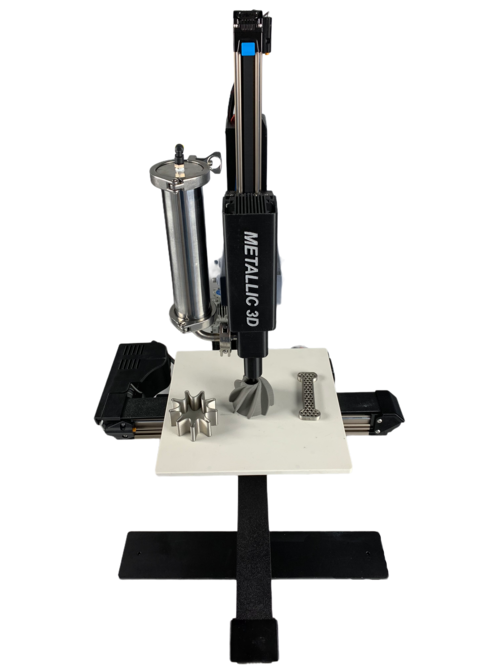

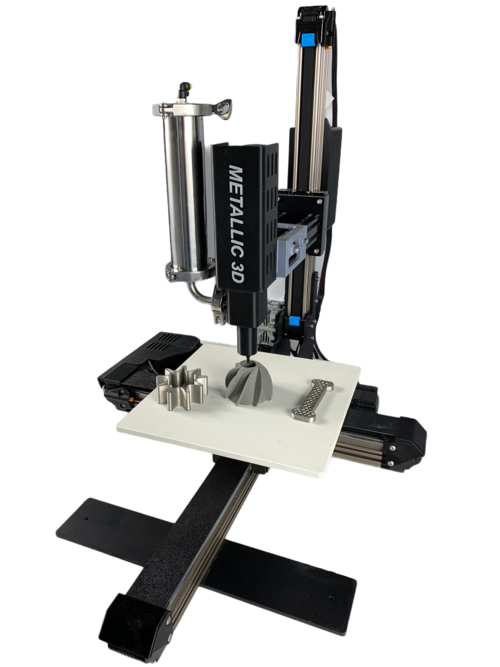

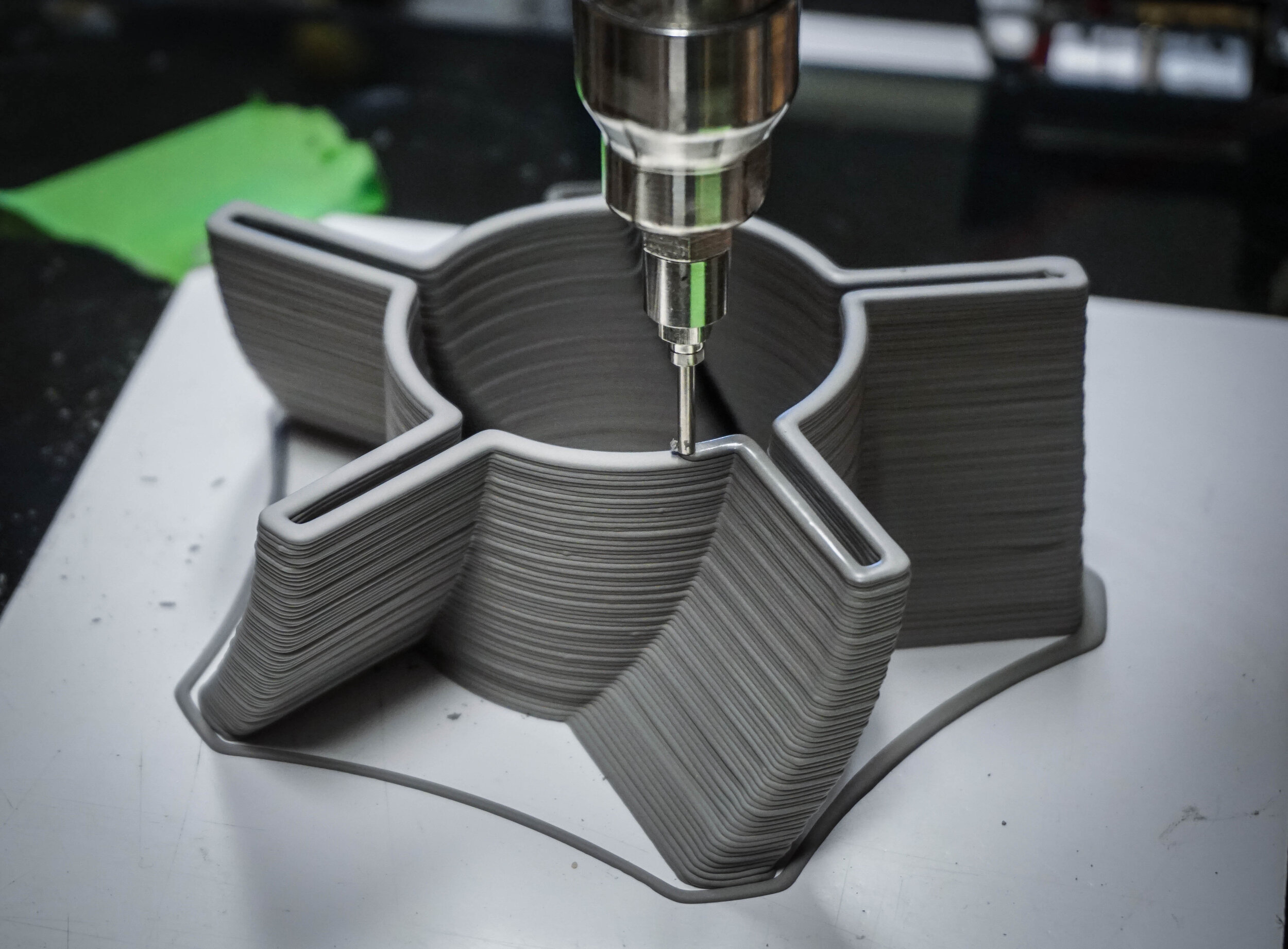

The Metallic 3D Printing System

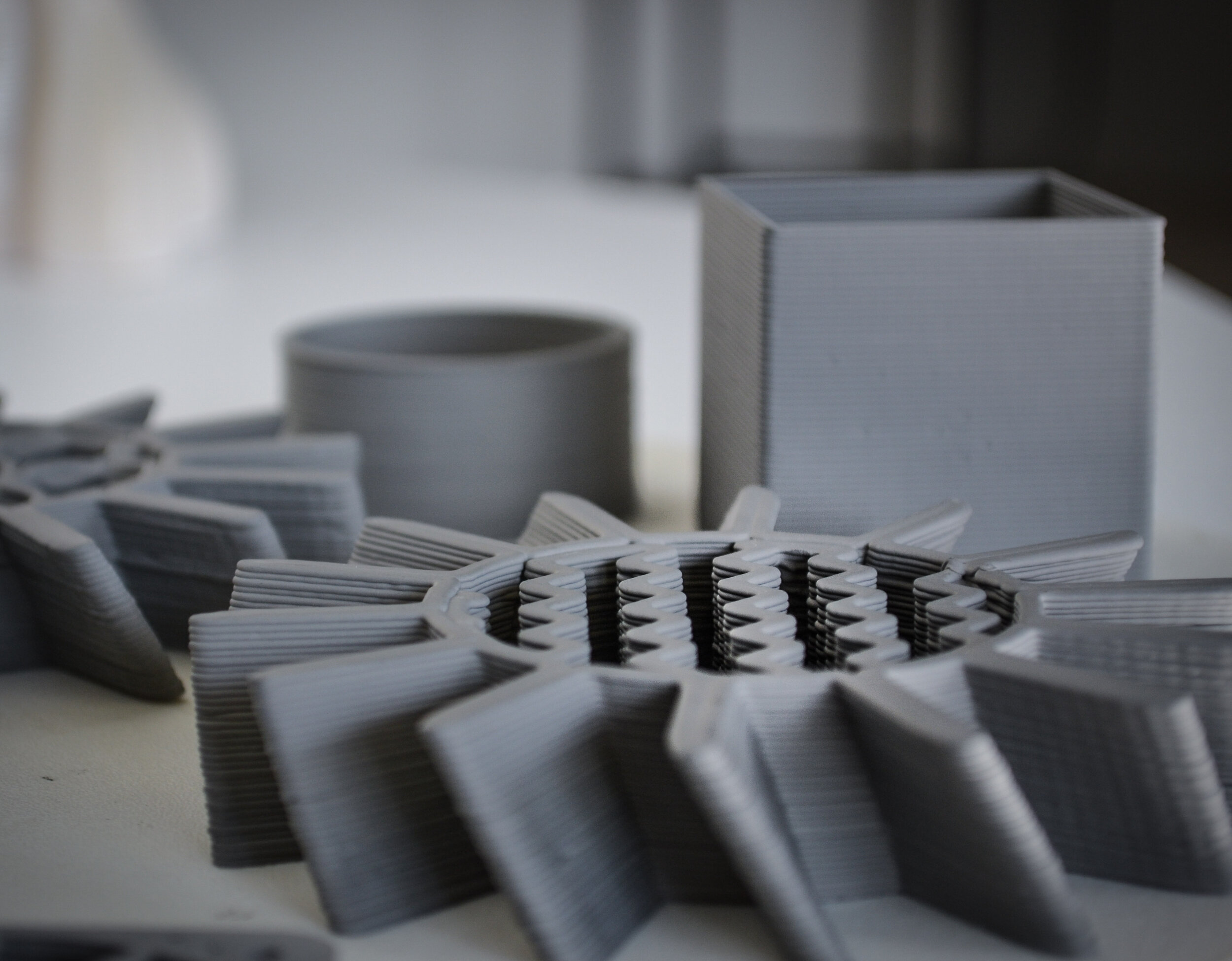

The Metallic 3D Print system is an extremely versatile 3D printer, handling a large variety of materials while making the entire process significantly more efficient and cost effective. this is made possible using our BMPD technology which unlike other printers does not need a filament and uses a solvent based feed-stock allowing you to skip the long and sensitive De-Binding process.

Metallic 3D BMPD printer specs:

Dimensional accuracy: ± 0.5 mm

Maximum part build size: 280 x 280 x 325 mm

Common layer thickness: 2.5mm down to 0.2 mm

Max build rate: 1,000 ml per hr.

Max build weight: 8 kilos per hr.

Feedstock Extruder Assembly: 1 to 5 Liters container

Regular environment temp.: 210C at 40% humidity

Nozzle diameter: 0.4mm up to 5.0mm

Nozzle material: Stainless steel, Nickle Coated Steel or plastic

Printing table: Acrylic or Carbon (Adhesion sheets recommended, i.e. ABS)

Software: Metallic 3D Fabricate GUI File types STL and OBJ

Browser requirements: Accessible via any web browser

Network connectivity: wireless on any device

Power requirements: 100-240-VAC (5 A peak)

External dimensions (HxDxW): 610 x 584 x 559 mm

Weight: 10 kg (22 LBS)

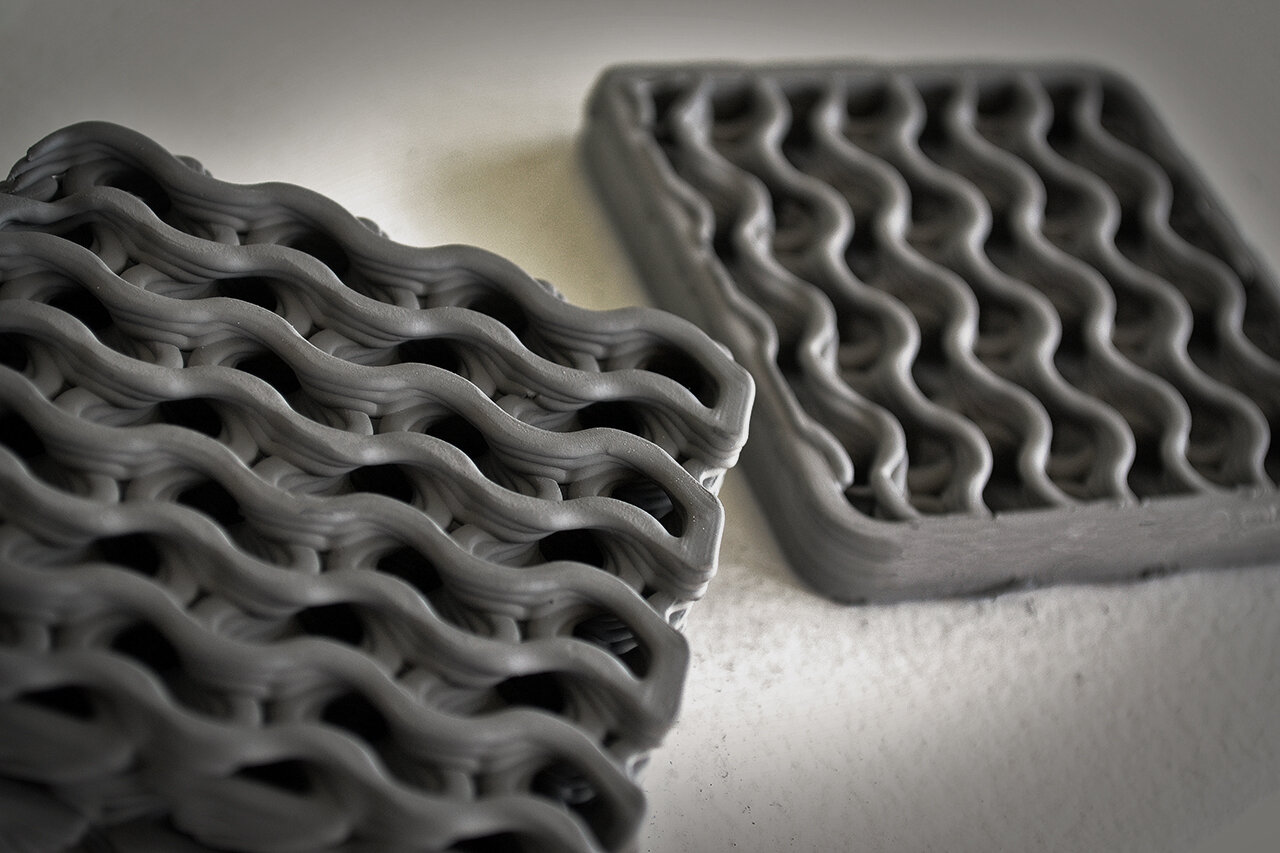

Materials for use with Metallic 3D BMPD print system.

METALS:

- STAINLESS STEEL

- TUNGSTEN STEEL

- TOOL STEEL

- COPPER

- NICKEL

- INCONEL

- COBALT CHROMIUM MOLYBDENUM

- TITANIUM

- ALUMINUM

- PRECIOUS METALS (Gold, Platinum, Palladium, Sterling Silver)

CERAMICS:

- ALUMINA

- ZIRCONIA

- SILICON NITRIDE

- GLASS

CERMETS:

- TUNGSTEN CARBIDE/COBOLT (WC-Co)

- METAL-BONDED DIAMOND COMPOSITES